Shbury was established in 2014, after over 10 years development, it has grown up to be one of the highly reputable Rapid Prototyping Company in terms of the service of CNC precision machining, CNC turning parts, injection molds, sheet metal.

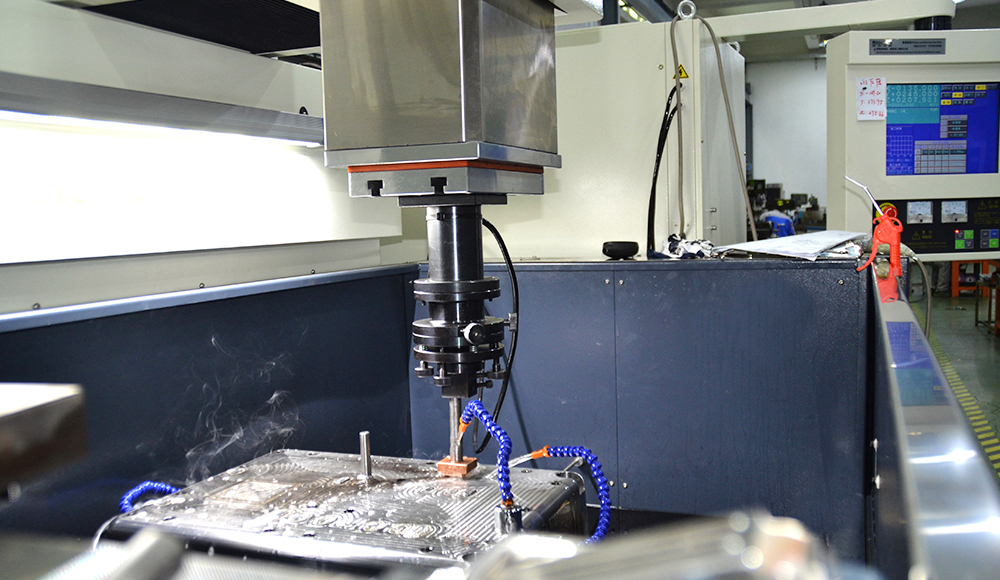

In Shbury there are over 40+ skilled technicians and engineers in a factory of over 4000 square meters, Equipped with 50 sets of CNC machines, EDM machines, injection machines, laser cutting machines, bending machines

Shbury based in South China, ShenZhen city – the engine room of China precision manufacturing – means that all of our resources are easily accessible. So this is also why we can become an OEM manufacturer. We have the ability to complete both a sample and a batch of assembled products.

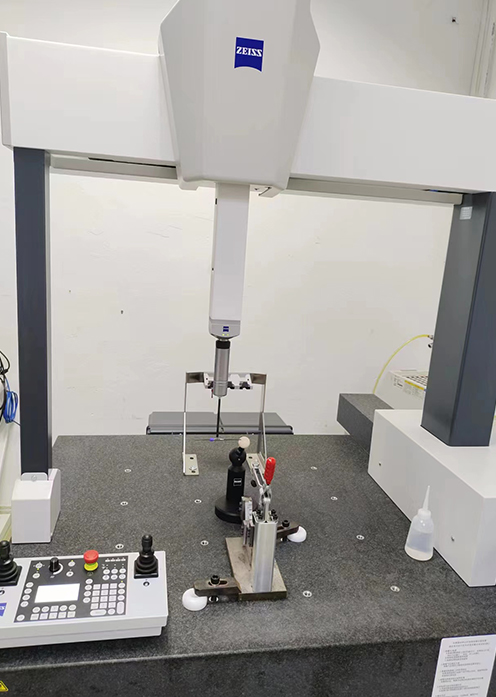

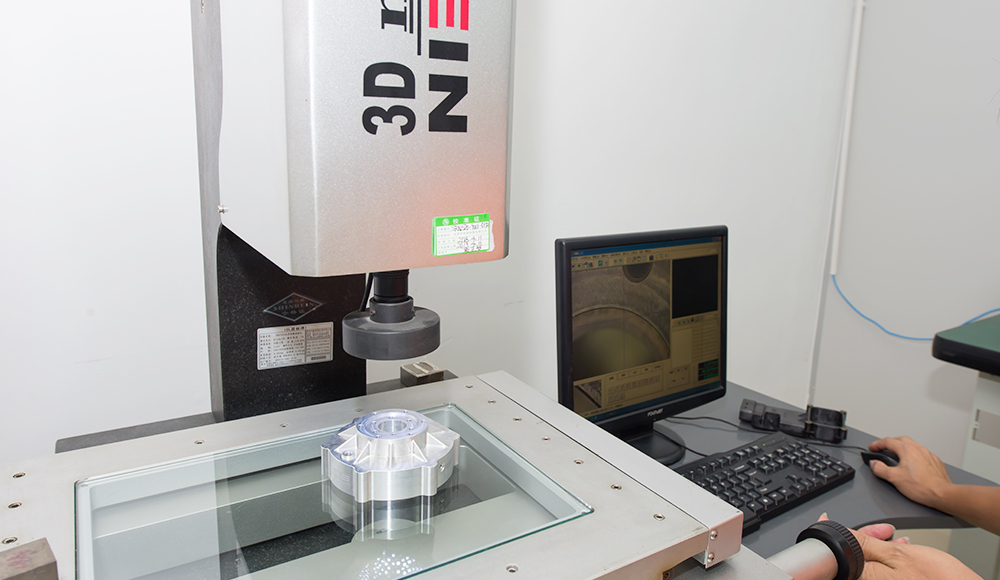

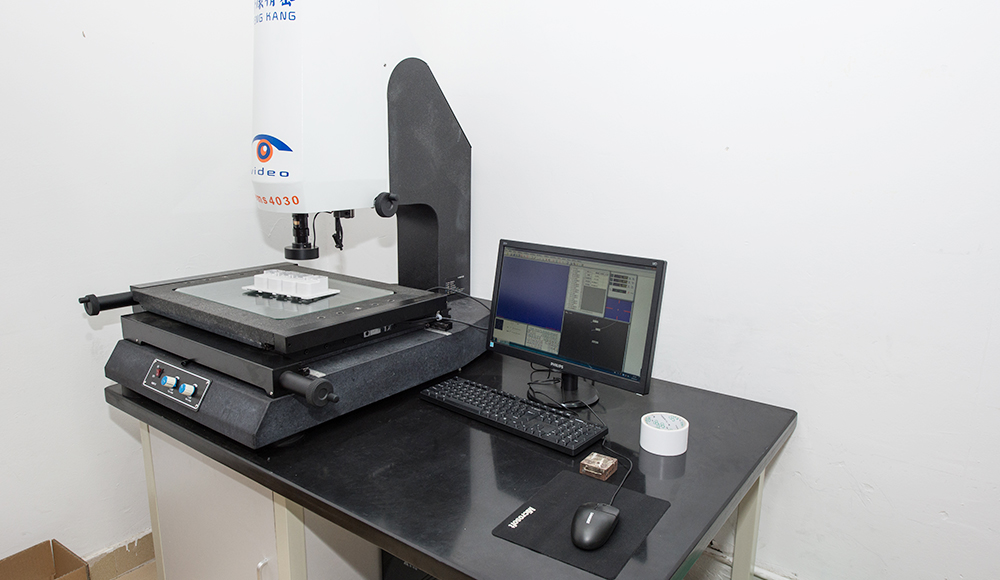

Detection and testing is also very strict, detection equipment including CMM, 3D scanner, caliper, inclinometer, micrometer, pin gauge, hardness tester and so on. We also test assembly according to customer requirements to meet customer needs.