When you’re in need of metal prototypes or parts with superior mechanical properties and specialized aesthetic design, anodizing aluminum is an excellent option. The anodizing process forms a layer of oxide on a metal part, effectively increasing corrosion resistance , and also enhancing visual qualities and keeping the surface from being scratched.

Anodizing aluminum is an extremely durable post-processing method. Not only does it enhance the properties and appearance of a part, it enables better adhesion for paint primers and glues. This technique utilizes anodic films that provide unique aesthetic effects, such as transparent coatings that reflect light or thick coatings that can absorb dies.

Despite having an impact on the mechanical capabilities of metal parts, anodizing aluminum will not take away from the natural appearance of the material. While the anodizing process can also be applied to other metals -such as titanium, zinc and magnesium- aluminum is by far the most widely used of the bunch.

As a part of Shbury's extensive offering for premium surface finishes , you can utilize our anodizing aluminum service to enhance the functionality and look of your metal parts and prototypes.

Powder coating is a popular finishing option in the CNC machining industry. It is a great way to impart improved physical and mechanical properties on custom machined parts.

This method of coating has been used since the early days of powder metallurgy and has become increasingly popular. It is widely used in industry today because of its numerous advantages, including corrosion resistance, high-quality surface finishing, and long-term environment-friendly impact.

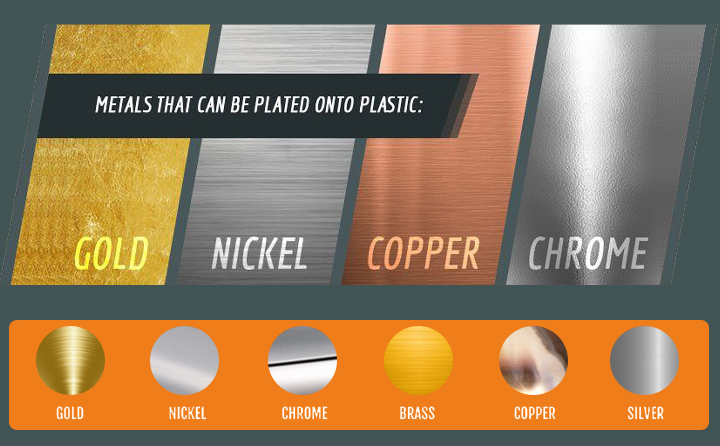

Plating is the process of covering a metal with a very thin coat of another metal for example: brass plated in silver, or steel plated in brass. The process is achieved by running an electrical current though a liquid solution via the plating material to the metal which is to be plated, forcing ions from the plating material to be deposited on the surface of the material that's being plated.

Considerations: Not all metals can be plated. Different grades of plating for external and high humidity areas. There are size limitations for plating larger items.

The metals of plating included nickel, chrome, copper and others.

plating can add durability, hardness, conductivity, and heat-resistance to your product, in addition to protecting against corrosion and enhancing its aesthetic appeal.

Spray painting, often simply referred to as "paint spraying" or " spray coating," is a method of applying a liquid paint or coating onto a surface using a specialized device called a spray gun or paint sprayer. This technique is commonly used in various industries and applications for its efficiency and ability to achieve even, smooth, and consistent paint coverage.

Paint Colors

We use the Pantone Matching System and RAL Classic System to match custom colors or paint samples. We can also do two-color or multi-color painting to obtain a more complicated appearance that looks like 2K molding.

Paint Finishes

We can supply different paint finishes, in matte, flat, semi-gloss, glossy finish, or satin finish. We can also simulate a specific Mold-Tech texture or soft touch to achieve a feel similar to the texture or over-molding of injection molded parts.

Functional Coatings

UV coating is able to resist ultraviolet radiation and protect the underlying material to enhance durability and wear or scratch resistance